Hey there!

We are Team Sonnenwagen Aachen - a solar racing team based in Aachen, Germany.

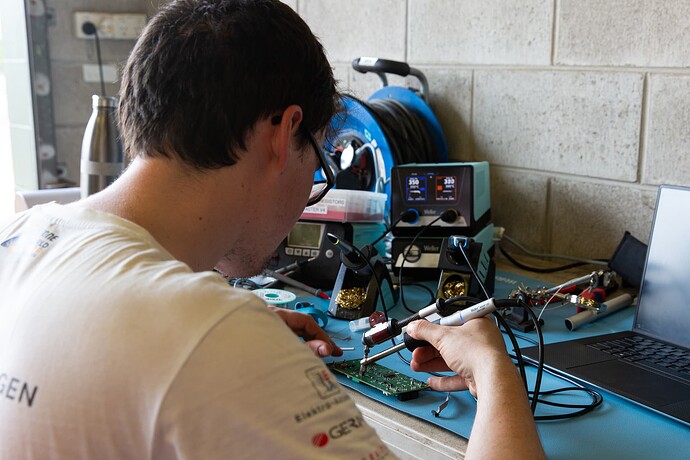

Consisting of 50 students from RWTH and FH Aachen Universities, we spend 2 years designing, building and testing a brand new one-of-a-kind solar electric vehicle, before racing it in competitions around the world.

Most notably: The Bridgestone World Solar Challenge; a 3000km endurance race across Australia. Starting in Darwin, the Stuart Highway takes us straight through the Outback to Adelaide. In between: Nothing but sand, heat, flies, and gigantic road trains.

As you can probably imagine, building such a car to not only complete the journey, but to be among the top teams on an international level takes not only a well-designed car, but - just as importantly - a reliable one.

Therefore, we set ourselves an ambitious goal: Complete the race across the desert without having to stop for repairs once.

To achieve this goal, we have built up a network of great sponsors and supporters that not only supply us with the monetary means to compete, but also assist us with their industry experience.

AISLER has been a long-time partner on our journey, providing us with PCBs for multiple of our cars, and always being there for us with any questions we may have had.

The inside of a solar car during the world solar challenge is rough terrain. Temperatures in the outback fall to single digits during the night, while commonly reaching 40°C during the day. Sand is everywhere, the sun is beating down relentlessly on any exposed parts, and the failure of any part is a disaster for race progress, or has safety implications for our drivers.

But they all made it! We drove almost 2800 Kilometers of these conditions during the race, plus a couple thousand more during testings in Australia and Germany before, without any failure on the PCBs.

Then, just 250 Kilometers before the finish line, caused by high winds and oncoming traffic, our car was pushed off the road and flipped into the bushes by the side of the highway. Luckily, our driver was completely unhurt. After the shock wore off, the team got to fixing. Even though the flip automatically removed us from contention, we wanted to show the world: Our car is safe. It can survive a high-speed crash on open roads, and not only keep the driver safe at all times, but is itself still able to run.

All electrical systems were miraculously still operational after absorbing the forces of a rollover. Our self-developed battery management system - of course consisting of PCBs manufactured at AISLER - kept monitoring the safety of the battery at all times. No PCB delaminated or showed any other issues of any kind. Even after all that mileage (once the dirt is wiped off) our PCBs still look fresh out of the factory.

Thanks to this resiliency, we were able to - at least ceremoniously - cross the finish line of the World Solar Challenge, gifting us a bittersweet end to our time on the continent.

I can’t imagine a more comprehensive real-world test than driving 4000 Kilometers in the Australian outback before crashing - and the PCBs mastered them.

This fall, the next, and polar opposite test will be waiting for these cars: The iLumen European Solar Challenge in Belgium; cold and wet. And we are confident that we will continue to be able to rely on AISLERs’ PCBs still… simply working.

Felix and the entire Team Sonnenwagen