I’m currently designing a tiny board with 32 castellated holes (8 at each edge).

As I’m going for quite compact population, there is no space for silkscreen marking. I searched a bit in general and got the hint to use the soldermask instead, which generates sort of a negative in the mask, thus should make a “golden marking”, provided the marking is on top of a copper fill.

So question is: is that supported, and if which are the limits (currently using this settings in KiCAD:

text height and width 0.3mm

thickness 0.05mm

The 0.3mm text height and width should not be an issue, the thickness of 0.5mm could work, but it’s untested. Regarding the PCB, could you please provide us with more details? We require a minimal board length of 10mm and at least two tabs/bridges to secure the board to the panel. These are ~ 4mm wide. What pitch and drill size would you use for the castellated edges?

Is there a tested thickness for the text? (also, I’d be willing to give it a shot for the first prototype boards).

I did noticed the in length and the board is 15.24mm quare.

I use a modified pin-header footprint with a 1.27mm pitch, which has 0.65drill size.

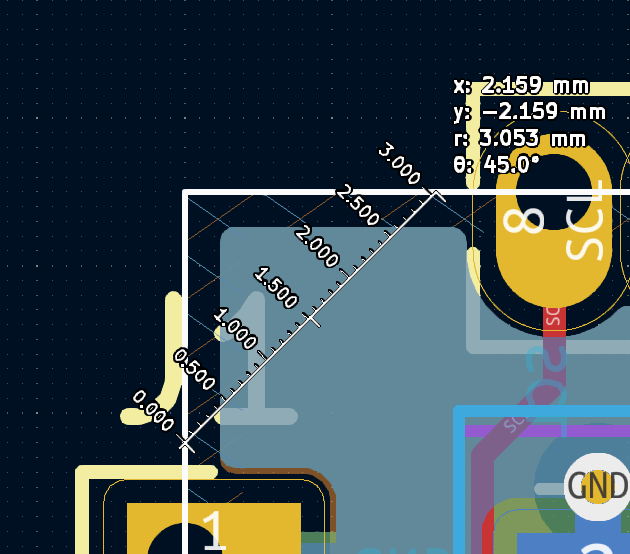

According to the measuring tool of KiCAD, I do have ~3mm space for bridges at the 4 corners. Would the 4 bridges compensate for the lack of the 4mm width? (screenshot attached)

We have not tested this method officially yet, thank you for pointing it out to us. We will run some tests soon. Our soldermask accuracy is relatively good. A friend of mine made this PCB art featuring small soldermask features, and it came out good. Thus, I’m feeling positive about your suggested values.

We currently only offer bridges in one size, we recently changed them from solid ones which were smaller to those who use drills to make separating easier. (Mousebites)

@Manuel-from-AISLER Maybe we should offer the option to select the bridge type to also accomedate these small designs.

First of all: Kudos to your friend for the piece of art.

I’ll give it a try with my values for this design.

As for the bridges: What if I do the the panelizing myself using solid bridges?

Increase the size 1mm in both directions is quite bit for that size of the board (it is meant to fit in a wrist/pocket watch in the end.)

Let’s see what Manuel makes of your suggestion.

You could panellize them yourself, but the Panels would need to still use our “custom bridge” marker on the outside, so our software picks up that you want to get castellated edges.

Please also note that the distance between boards needs to be 2.4mm at minimum so that we can use our milling tool.

I am happy to assist if you have questions.

Thanks for the reply.

As I’m not in a much hurry with this, I’d like to wait What Manuel form aisler says to the “having both options of bridges” .