Reliable testing is essential in the development of embedded systems - and at the same time very time-consuming. Complex test environments, tools that are difficult to use and a high level of manual effort make it difficult for many companies to work efficiently.

This is precisely where we at emintes want to come in with our embedded test platform. With the clear motto “Make testing easy”, we have developed a solution that makes it easier to get started, speeds up daily work and increases test coverage at the same time.

The basic idea - no more overengineering

Most test systems on the market are overloaded: They offer many functions that are rarely used to their full extent. In some cases, proprietary or rare-known programming languages are used, which requires a corresponding learning curve before the system can be used properly. Last but not least, complex systems always bring with them a great potential for errors and lead to time-consuming troubleshooting.At emintes, we take a different approach: with our test platform, we focus on the essentials. KISS (keep it simple stupid) is our guiding principle. This enables a quick and uncomplicated start in the world of automated testing - without specialist knowledge or complex setups. The tests are written in Python - one of the simplest and most popular programming languages in the world. Simply plug in and get started straight away.

Universally applicable - from the first prototype to series production

The emintes test platform was designed to be universally applicable. It accompanies the entire product life cycle - from development to production to complaints.Development: Continuous testing, direct feedback:

Manual firmware tests are time-consuming, sometimes not reproducible and usually only achieve low test coverage. With the emintes Testbox, tests are not only automated, but also documented - including a test report. Integration in CI/CD tools such as GitHub, GitLab or Azure ensures that the entire functional scope of the software is automatically tested every time the code is changed. Errors are recognised immediately and can be fixed directly by the developer before they move on to other topics - this ensures a fully functional firmware at all times, which is tested daily with a very high test depth. Different product variants can also be tested very easy in parallel during each run.Example: How to get to the first prototype faster through test automation

Production: Check efficiently, ensure quality

Testing devices in series means time pressure. Whether circuit board tests or final device tests - our test box allows testing in parallel and replaces many manual steps. This guarantees that the test will never again become a bottleneck in your production. And the best thing is: if you have already used the test box in development, you can simply reuse the tests from development in production - this saves time, reduces sources of error and makes collaboration between development and production much easier.Complaints: Analyze and document errors with just one click

If a defective appliance comes back to you as a complaint, you can simply run the final tests from production again at the touch of a button and find out very quickly which fault the appliance has. Faults are automatically documented and logged in a database. This gives you a very good overview of the most common faults and allows you to identify potential improvements for your product without much effort.Fast start, thanks to Aisler

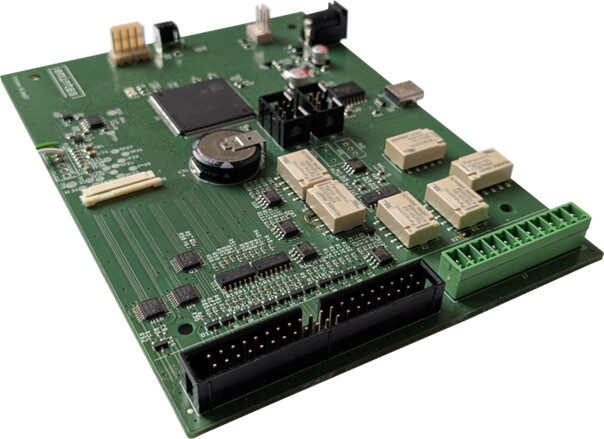

As a young start-up, you are constantly caught between brilliant ideas and scarce resources in the initial phase. Every euro has to be used efficiently - especially if you don't have a finished product yet. It was the same for us. We had a clear vision of how our test platform should be implemented.Prototypes are needed to evaluate the idea. Here we quickly faced our first financial challenge: how do we get an assembled circuit board that we can use to test our idea in practice?

The reality for many manufacturers is that assembly is only available from ten pieces upwards. For a start-up with a limited budget, still in the design and experimentation phase, this is a huge challenge. After all, what’s the point of having a bunch of circuit boards if you don’t even know if the first design is going to work?

The solution: Aislers amaizing assembly

After some research, we came across Aisler, whose possibilities brought us closer to our goal. Because here we were offered:- No minimum quantities: We were able to have a single circuit board manufactured and assembled - ideal for laboratory use and validation of the initial design.

- Production in Germany: For us as a company that values data and IP protection, this was a huge advantage.

We were able to get started straight away with the supplied circuit board and check our design. Minor design errors were quickly found and corrected. The first firmware was created and it became clear that one or two microcontroller pins still needed to be swapped in order to be able to use the peripherals even more efficiently. This is exactly what the first circuit boards were intended for. And: this is exactly why it was so important not to have to produce ten boards at once.

Building the first prototypes

Once the initial design problems had been solved, we took the next step: we wanted to build the first prototypes. That's why we had additional circuit boards assembled in small quantities, which we used to build the first prototypes of our test box - this time for real pilot customers. The aim was to test our test box under real conditions in the field.What comes next

Extensive functional and stability tests are currently being carried out with the test box in real operation. This allows us to gather valuable feedback from our first pilot customers directly from the practical experience of their development and production environments. And for sure – every test box will be tested by a test box in future 😊Further pilot customers wanted

Curious about the test box? We currently still have prototypes available to serve other pilot customers. Be an early adopter and benefit in several ways:- Influence development of the test box

- Early access to innovative technology

- Direct line to our developers

- Start optimizing your processes today

- Cost savings through special conditions

- Visibility as an innovation partner

Contact us: info@emintes.de