Hello,

We’re considering having assembly done by Aisler in the future (several months away still). However, we’re a bit worried about assembly details concerning the THT parts that we feel are somewhat important, see below.

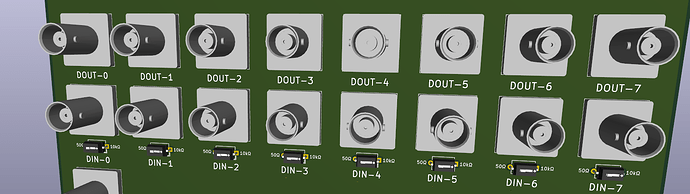

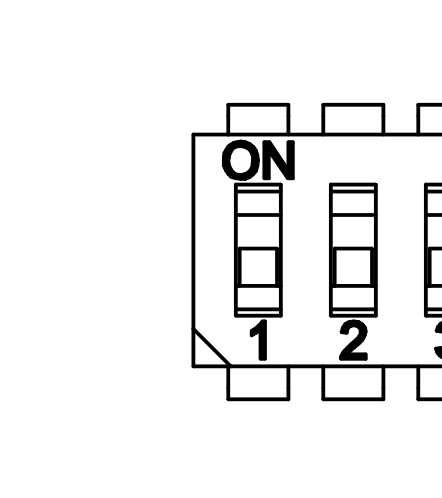

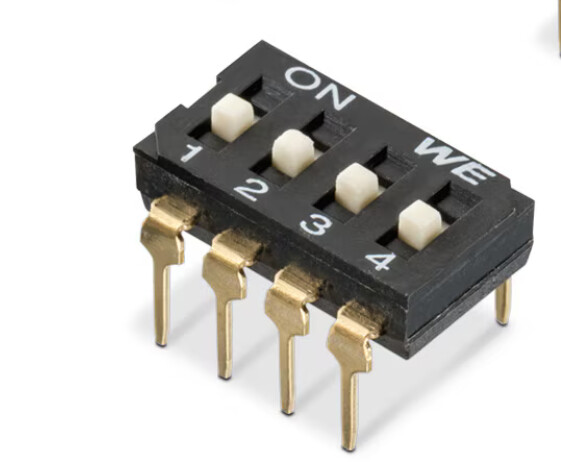

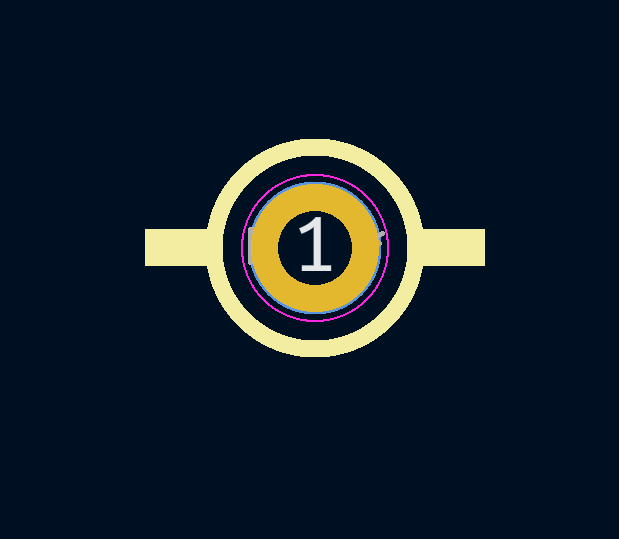

In particular, we’d like all BNC connectors to be rotated as shown in the picture (with the bayonet clips aligned horizontally), and that the DIP-switches (just above the DIN labels) are in the correct orientation.

How can we minimize probability of human error in cases like these? In the past, we’ve seen quite a few issues where the people doing the soldering made mistakes, and we’d like to prevent that as much as possible.