Please link your Shareable link here:

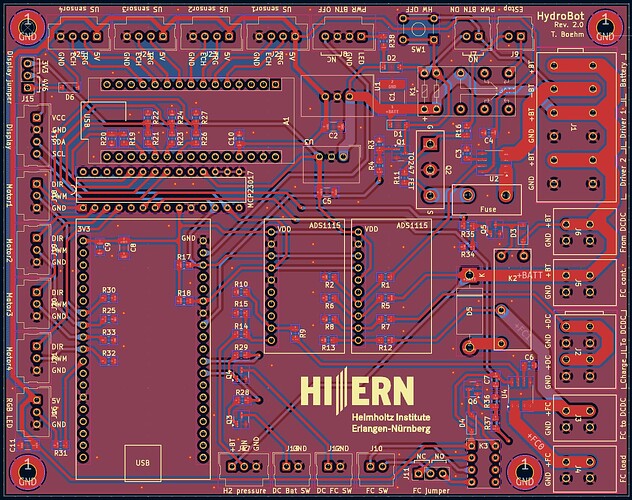

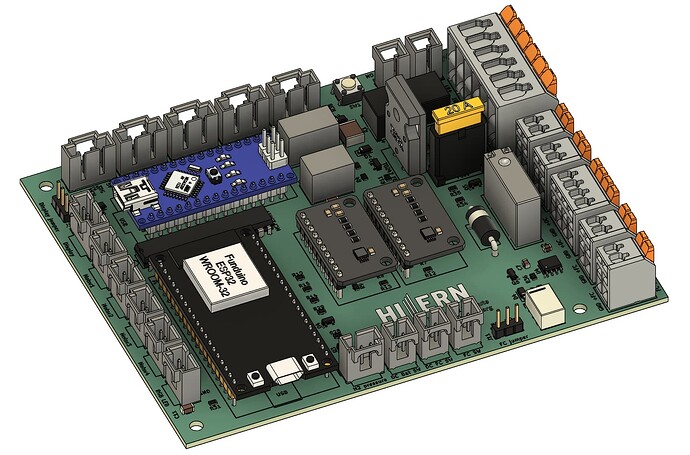

Robot PCB

1. Why I started with this project?

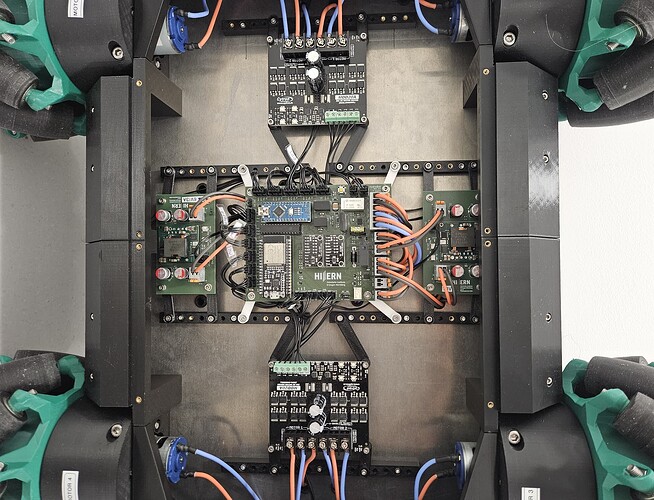

HydroBot is a project developed by the Helmholtz-Institute Erlangen-Nürnberg for Renewable Energies. It is a demonstrator platform for fuel cell electric vehicles. A remote-controlled robot was developed that is powered by a proton exchange membrane fuel cell, and that uses Mecanum wheels for propulsion. This prototype is intended to get a glimpse into system integration of fuel cells for the involved researchers at the institute, and to provide hands-on material to external audience at fairs.

HydroBot uses a 60 W hydrogen fuel cell stack from Horizon Educational to power its electronics and charge its onboard battery, a 12.8 V LiFePO4. The battery is used to power the robot and the fuel cell controller during startup. Once the fuel cell is online and providing power, it takes over this task. The robot is a remote-controlled mobile platform, which can drive in any direction using its four Mecanum wheels, each with its own motor.

More information on this project can be found on GitHub.

The robot uses custom electronics with an ESP32 microcontroller as the main “brain”, which allows wireless remote control using ESP-NOW, and that controls the motor drivers, the fuel cell controller, an LCD, LED status lights, and that reads various sensor data to send telemetry data to the remote control and ensure safe operation. An Arduino Nano is used as a second microcontroller to read data from ultrasonic distance sensors, which are then forwarded to the ESP32 to allow it to stop the motors if an obstacle is detected in close proximity. Most of the electronic components of HydroBot are mounted on a single mainboard, which allows for a compact and clean design.

2. What I love about electronics?

Electronics are basically everywhere in today’s world because they offer almost infinite options to make machines more efficient and intelligent, and it is thrilling to be able to create circuits and circuit boards on your own that turn an idea into reality - even if it is only a small and simple project!

3. Which PCB Design Tool I use and why?

The PCBs for HydroBot were created using KiCAD, because I had some previous experience with this software, and I love the idea of sharing knowledge and tools open source.

4. What’s my greatest fail with the project?

The robot required a complete remake of its mainboard as the first version did not successfully allow the integration between the fuel cell stack and battery of HydroBot. The issue was related to how the two components were interconnected: Initially, a buck-boost converter was used to convert the variable voltage output of the fuel cell into a stable voltage-current profile for charging the LiFePO4 battery. However, the fuel cell repeatedly ran into a safety threshold with this design. Hence, a second revision was needed, which uses a direct connection between the two components, secured by a diode and a relay, which prevents current backflow from battery to fuel cell, and which allows to galvanically insulate the two components when needed. This configuration forces the fuel cell to operate at the voltage of the battery. The voltage level of the 4S LiFePO4 is in a suitable range for this fuel cell stack so that an efficient and safe operation of the fuel cell is possible, and since the fuel cell’s voltage can’t drop below the battery voltage, no safety threshold of its controller can be triggered any longer.

5. What’s my greatest win in the project?

HydroBot includes a custom-designed circuit that allows to switch it off remotely via software. To this end, a bistable relay is used, which uses two separate coils to set and reset its contact position. This relay is connected to the power button of the robot, and it is used to drive a high-power MOSFET that acts internally as the main power switch. Hence, the power button switches the robot on (but not off when it is released). The reset coil of the bistable relay is connected to the microcontroller of HydroBot, which allows the user to switch it off using a software command. It is not a compact circuit, but it works reliably and does not draw any current when the robot is switched off - and I like the simplicity of this configuration!

6. What’s my most favorite feature AISLER?

AISLER agreed to sponsor the PCBs for HydroBot, which was a great help for us in this project. Many thanks to you guys for that! Of course, the fast turnover times and the high quality of the PCBs is greatly appreciated, too! ![]()