Hi everyone,

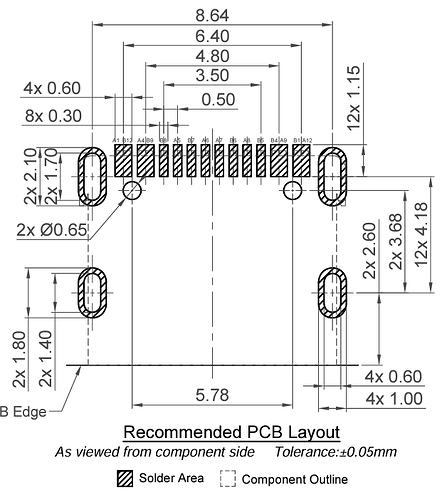

I’m currently working on an project with an USB Type-C Connector: (https://www.digikey.de/de/products/detail/gct/USB4085-GF-A/9859662)

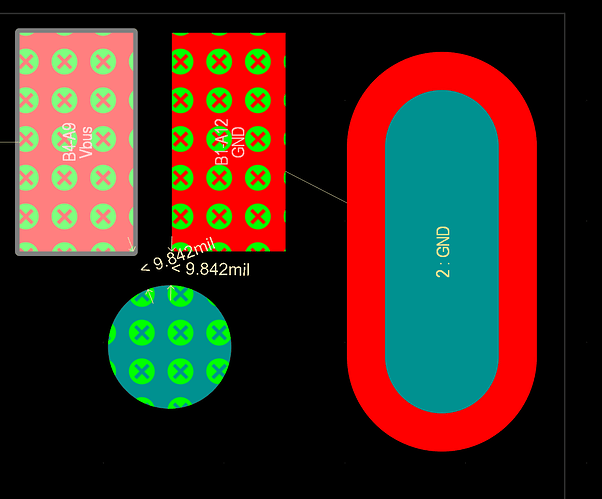

I got the footprint for the connector and integrated it in my design. Problem is, that my design rules throwing errors, because of the annual ring size of each pin. Its 0.125mm instead of 0.2mm. My Question is now, what can I do, to use this connector. I cant make the annual ring bigger, because the space between each hole would be too small. What will happen, if I order the pcb with this design?

Thanks a lot.

We would choose the next largest drill bit, this would be 0.4 mm if you selected the complex and 0.45 mm with the simple design rating. We specify 200 µm annular rings in the Design Rules to allow for drill size compensation. If you select the complex pool, we would be able to fabricate the boards because we do not compensate the drill in that particular case.

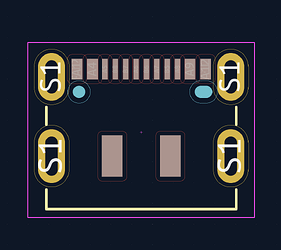

I however, highly recommend the usage of an SMT USB-C connector which provides benefits over a THT based USB-C connector.

- They are easier to source.

- Offer a lower price.

- Easier to solder

- Can be fabricated with the simple design rule rating

Hi, question. I am looking for that SMT connector, like the USB4105 from GCT. As for a complex board, the clearances are mentioned in https://community.aisler.net/t/pcb-design-rules/41:

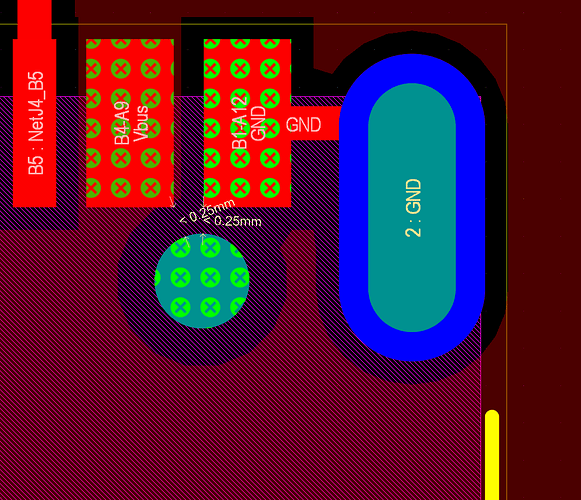

o min. spacing NPTH / SMD-pad 250 μm 250 μm

The distance between the two non plated holes under A1/B12/A4/B9 and B4/A9/B1/A12 are less than 250 um… Can you give me a suggestion?

It seems like the light blue holes are also very close to the pads in your screenshot. Aisler has a 0.250 mm rule between holes and pads, how did you overcome?

The pad and NPTH hole of the connector I shared are 300µm apart.

The 250µm rule is to prevent accidental plating of the hole, during manufacturing. The NPTH gets covered with a protective coating, which needs to safely attach. Since the hole is just for a non-conductive plastic bit, a clearance of less than 250µm should not be too much of an issue as long as no other copper features are shorted together.

Thank you for the reply!