Introduction

The Bill of Material, or BOM for short, lists the kind of components and their quantities required to assemble a PCB. In this article, we describe how to optimize your BOM and provide useful hands on tips.

What are typical problems with BOMs?

Many products are developed without the assembly process and component availability in mind, resulting in higher prices during manufacturing and greater risk of components becoming unavailable.

The main problems with BOMs are often:

- High part variance

- Unnecessarily small passive components (resistors/capacitors/inductors)

- Specifying obscure components where generic parts could have been used.

- Specifying specific MPNs for passives.

High Part Variance and unnecessarily small components should be avoided due to the limitations of pick and place machines. The machines have a limited feeder capacity, if this capacity is exceeded, it is required to set up an additional machine, resulting in extra work and thus cost.

Unnecessarily small passives, will also increase the cost, due to the added complexity, try to use 0402 (imperial), 1005 (metric) as minimum where needed and 0603 (imperial), 1608 (metric) for the majority of components.

Steps to optimize a BOM

The objective of BOM optimization is to reduce the part variant, and make it easier to source components. This can be done by re-using the same component multiple times, using more integrated parts, and choosing common sizes for passives and jellybean parts.

Re-using components

The simplest way to reduce part variance is to re-use the same component. As an example: A project requires two transistors, one switches a 100mA load, the other an 1A one. Instead of using two different transistors, the beefier transistor can be re-used for the 100mA load, reducing the part variance. The same concept can be applied for other types of components

Integrated components

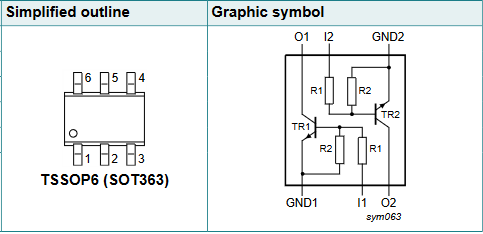

Integrated components help designers to achieve their design goals while keeping the component count low. An example of this are resistor equipped transistors (RET) which include the biasing resistors, reducing part variant and lowering the assembly cost. The RET shown includes two transistors and four resistors in a package, so instead of 6 individual components only one needs to be placed, reducing the assembly cost by 15 Cents. This simple change can make a large difference in assembly cost for larger runs.

Common component packages

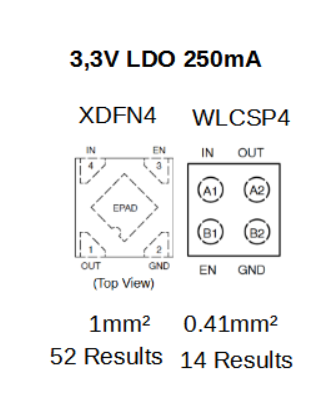

Obscure components are more likely to be become unavailable. Thus, it is advisable to use a common component and package.

This is example shows the difference between two packages for a 3.3V LDO, the more common XDFN4 package yields 3,7X more search results at a component distributor than the lesser used WLCSP4 package.

Getting your passives in order

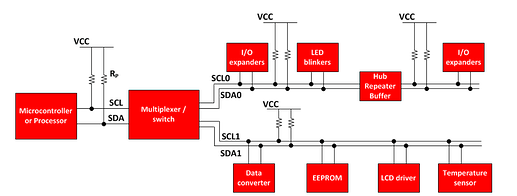

Resistors and capacitors are the most used components in an electrical circuit. The usage of resistors ranges from current limiting to pull-ups/downs. Capacitors are used for decoupling, smoothing, and energy storage. To optimize your usage of passive components, it is required to understand which function the component serves. Is my resistor used as pull-up, to current limit or as a sense resistor? Is my capacitor for used for decoupling or in a precise analog circuit? This determines what your options are. A sense resistor, for example, needs to be accurate and able to tolerate a larger amount of power, so it makes sense to pick a specific part. Pull-up/down resistors, however, can be optimized more easily, for example, the 5.1KΩ pull-down resistor needed for USB-C can also be used as pull-up for a I2C bus instead of the 4.7KΩ one specified in the datasheet.

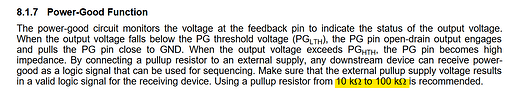

Before blindly changing components however, it is a good idea to verify that the change will not negatively impact the circuit’s performance. In our I2C bus example, we can refer to this Appnote to calculate the minimum and maximum resistance value for our pull-up and see if the 5.1KΩ is suitable. Generally, it is always a good idea to take a closer look into the components datasheet, this screenshot taken from a LDO datasheet shows that a pull-up of 10KΩ to 100KΩ is recommended for the Power-Good pin. So if we use another resistor in this range already, we know that we can re-use it.

The design procedure is very similar with capacitors, identify the function, take a look into the component’s datasheet, consult application notes and verify your change. For capacitors, it is important to include the maximum voltage, capacitance tolerance, ESR and DC-Bias in your design choices.

Generic passives

For best availability and pricing, generic passives should be used where possible, this means that you specify the component properties rather than a particular part number. Our Smart Match tool will find the best match at the lowest price.

With Smart Match, you can specify components present in the E48 series. Which have a working voltage up to 50V working voltage and a maximum 1W power rating.