Some connectors need a cutout in the PCB, and even with large-ish holes to clear the corners, the board inspector complains (which is ok, given the current rules):

Those are a 4-pin 3.5 mm audio jack (top) and an MMCX connector (bottom), and having smaller allowed radii would really neaten things up a bit. I’ve used 0.8 mm holes just touching the connector edge (= should be cleared by a 1.6 mm mill bit), so they should be fine with minimal manual work now. Still, it’s not really beautiful.

Regards

Christoph

2 Likes

Hi Christoph,

Thank you for your request. In our opinion, the currently available milling tools (diameters: 2.4 mm & 1.6 mm) should be sufficient for most applications.

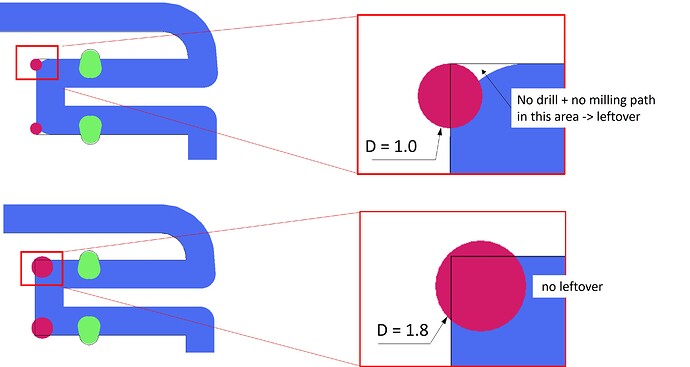

Rectangular cut-outs are indeed problematic because the corners (without radii) cannot be milled completely with a round milling tool. There will always remain a leftover. Even a milling tool with a smaller diameter cannot solve this problem in principle.

Basically, additional holes are a good idea to prevent leftovers in a rectangular cut-out. However, you would have to make them larger and arrange them so that the contour is completely covered. Please see the picture below:

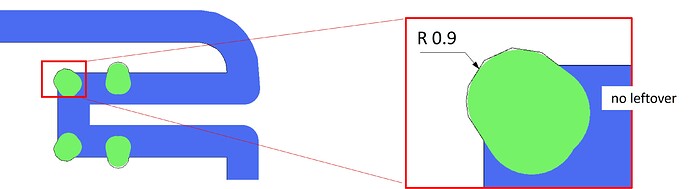

Alternatively, you can redesign the contour in the affected corners so that we additionally use our smallest milling tool (1.6 mm, color green).

I hope this helps you with your problem.

For your information: The ProcessingNote “Outer milling paths missing and/or incomplete” only considers the outer contour and the generated milling paths. If you want to remove the leftovers with the help of additional drills, these notes will still be visible.

Best regards,

Manuel

Thank you, I’ll try that way of placing the holes in the next revision!