Press-Fit

Press-Fit describes the process of creating a strong electrical and mechanical connection between a component and the PCB without soldering by pressing the pins of the component into the copper of a plated through hole.

Press-Fit is currently only supported on the 4 Layer 1.6 mm ENIG pool.

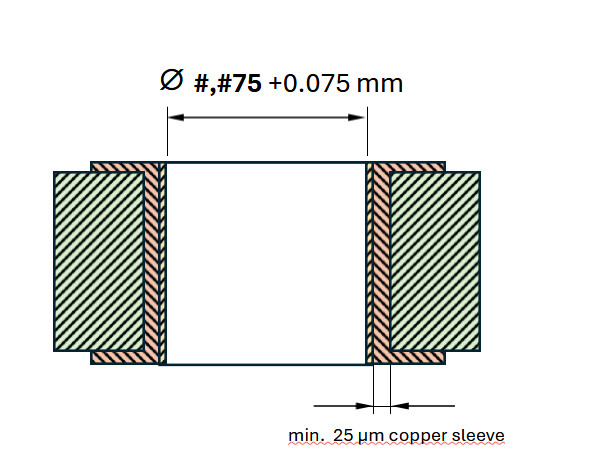

As Press-Fit components require a lower tolerance of the final hole diameter, they need to be specified in the CAD data, we automatically detect drills if their diameter is set to #.#75 mm for example 1.475 mm, drills with a final plated hole diameter between 0.575 mm to 5.675 mm (22.63 mil to 223,42 mil) are supported.

Würth Red Cube Footprints designed for ENIG surface finishes are automatically recognized, when using a different Press-Fit component select the closest matching diameter and adjust your footprint accordingly.

The plated through hole will be manufactured with a minimum copper thickness of 25 µm and a maximum tolerance of +75 µm.