Hello Aisler Community,

We are the Sapienza Rocket Team from Università di Roma La Sapienza. This year, our mission culminated in participating in the 2025 International Rocket Engineering Competition (IREC), hosted by the Experimental Sounding Rocket Association (ESRA) in Midland, Texas.

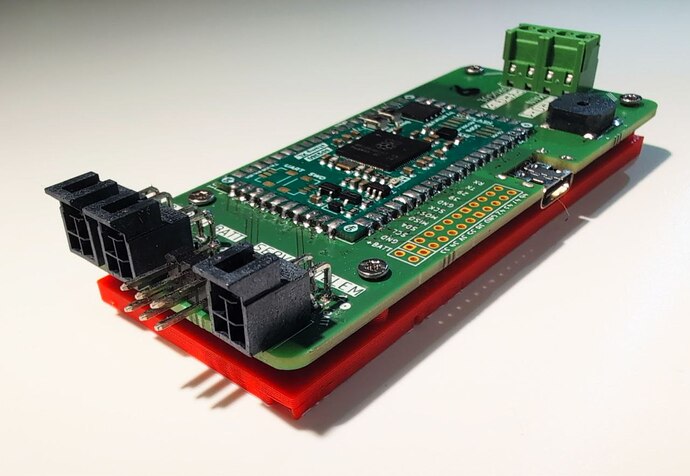

Central to our sounding rocket’s operation was a custom-designed flight computer called “Ulysses,” brought to life with the critical support of Aisler.

The Avionics Challenge: A Leap into Custom PCBs

Two years ago, our Avionics Department began as a small team of three enthusiastic but inexperienced students. Our first goal was to develop a custom flight computer and tracker. While initial prototypes on basic breakout boards were functional, they were too bulky for our ambitions. To advance, we knew we needed to reduce the size and increase the sophistication of our electronics, which drove our decision to design our own Surface Mount Device (SMD) boards.

This leap required a complete change to our design philosophy. Thanks to Aisler’s rapid production services, we could afford to make mistakes, learn, and quickly iterate on our designs. We named the board “Ulysses” to represent the odyssey we expected during its development, and it ultimately lived up to its name. With each board revision, we honed our skills, eventually mastering the complex process of designing and soldering fine-pitched SMD packages.

Ulysses: Technical Specifications

The primary goal for Ulysses was to reliably manage recovery systems, log flight data, transmit telemetry, and control the vehicle’s active air-brakes. To achieve this, we integrated the following components:

-

Microcontroller: We chose the Raspberry Pi RP2350B. This gave us a dual-core ARM Cortex-M33 processor and access to 48 GPIOs.

-

Power System: A stable 5V supply, powered by a self-assembled 2-cell (2S) Li-Ion battery pack, was ensured by an MPM3610 switching buck converter.

-

Pyro Channels: For deploying parachutes, we engineered pyro channels using a specialized automotive switch for its current-limiting capabilities, paired with MOSFETs for reliable pyro detection and firing.

-

Sensor Suite: The board was equipped with a Bosch BMP390 barometer for precision altitude readings, two STMicroelectronics LSM6DSO32 6-axis IMUs for orientation and acceleration data, and an STMicroelectronics LIS3MDL 3-axis magnetometer.

From Design to Reality: Our Development Experience

Integrating the sensors posed our greatest challenge. The extremely small footprint of these components, with pads down to 25 microns, initially caused significant soldering issues. The solution came directly from the Aisler community; a forum post helped us realize we were using the wrong solder paste. By adjusting its composition with a specific solvent, we achieved consistent, reliable soldering.

Another valuable lesson was learned during flight tests: we discovered the LIS3MDL magnetometer was placed too close to the servo power tracks, causing interference that prevented it from working correctly during ascent: a classic real-world engineering challenge.

Roccaraso Proving Grounds and the Training Academy

We produced five functional Ulysses boards, which underwent their first critical tests at our local proving grounds in Roccaraso, Italy. The boards flew on our main competition rocket, smaller rockets from our Training Academy, and also on our CanSat deployer named “Caronte”, where Ulysses helped collect mission data for a high-school science project.

Our Training Academy is a core part of our mission, providing dozens of students with a hands-on program to learn physics and engineering by building their own low-power rockets. While our main rocket’s test flight was a success, the trainees’ rockets… expectedly… had some failures. These moments, while leading to the loss of some electronics, provided crucial learning experiences.

Competition and a Testament to Durability

At IREC 2025, after motor burnout, our rocket suffered an anomaly that led to the premature activation of the parachute deployment system by one of the Commercially Available Flight Computer installed alongside our own Flight Computer. After the failure, our rocket descended along a ballistic trajectory that ended with a high speed crash into the ground. We were able to recover what remained of the boards from the wreckage and the Ulysses Flight Computer, built on an Aisler PCB, was still perfectly intact—a powerful testament to the sturdiness of the manufacturing.

This surviving board now sits in our trophy cabinet, representing the immense learning, progress, and resilience that define our team’s odyssey.

Thank you, Aisler, for your outstanding support and high-quality manufacturing that empowered us to turn ambitious ideas into reality.

The Sapienza Rocket Team