Hello fellow makers,

We are Campus Tirol Motorsport, the Formula Student team from Innsbruck. Each year, we design and build a brand-new electric race car to compete in international Formula Student events against university teams from around the world.

Aisler has been our primary PCB supplier since 2021. Their excellent online Gerber viewer and support for KiCad board files make ordering PCBs quick and effortless. The high quality of their boards, combined with fast manufacturing and short delivery times, significantly streamlines our development, testing, and iteration processes. And when mistakes happen — and they definitely do — Aisler’s revisioning tool becomes an invaluable asset. It allows us to easily order updated versions of our PCBs, helping us stay on schedule throughout the car-building process.

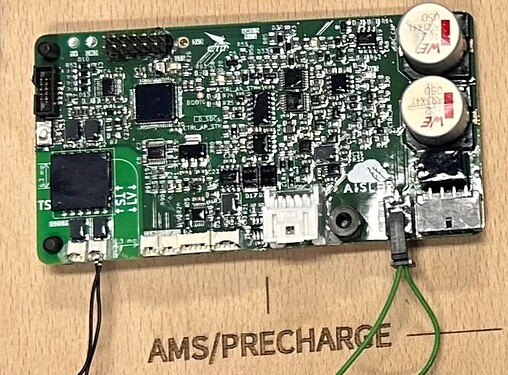

This year, we developed the fifth revision of our custom Accumulator Management System (AMS) — responsible for monitoring all temperatures and voltages within our 600V accumulator. The system consists of three main components:

- Accumulator Management System (AMS): Logs all data from within the accumulator

- Cell Supervision Circuit (CSC): Measures each cell’s voltage and temperature

- Precharge Circuit: Precharges the high-voltage capacitors of the inverters

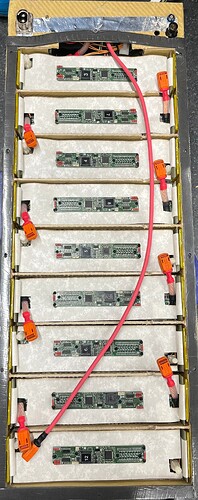

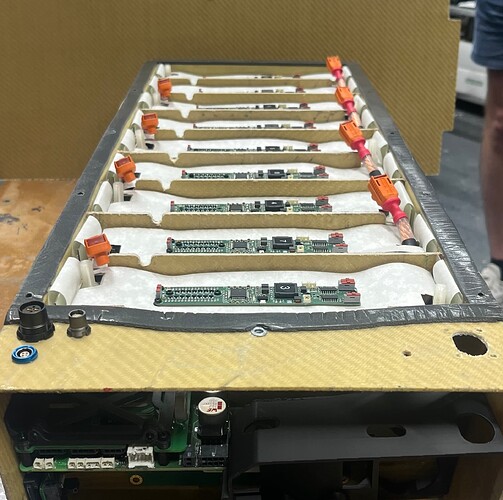

Our 600V accumulator powers the car and is built from nine stacks, each containing 30 cells arranged in a 15s2p configuration (15 cells in series, 2 in parallel). Each stack includes a permanently attached CSC Mech, which houses all temperature sensors and provides access to individual cell voltage measurements.

On every CSC Mech is an EEPROM, used to store a unique Stack ID. This enables quick CSC swaps and automatic stack identification for monitoring. Additionally, we store a custom cell model for each stack in the EEPROM to improve accuracy in state estimation.

On top of the CSC Mech sits the CSC board, which features an LTC6812 IC and two multiplexers. The LTC digitizes the voltage and temperature data and transmits it via ISO-SPI to the AMS. The LTC also handles cell balancing by correcting voltage drifts over time to ensure optimal capacity and performance from the accumulator.

At the heart of our accumulator electronics is the AMS, which manages two ISO-SPI channels in a circular topology to communicate with all nine CSCs. It also controls the high-voltage relays on both the positive and negative terminals of the accumulator output. The system is connected to the car’s main CAN FD bus, enabling real-time monitoring of all accumulator data.

We’re proud to have Aisler as a long-term sponsor and sincerely thank their entire team for their continued support over the past few years. Together, we’ve celebrated our first podium finishes in international Formula Student competitions — and we’re aiming for many more in the future.