Hello fellow makers,

We are Campus Tirol Motorsport the Formula Student Team from Innsbruck. Every year we build a new electric race car to compete in international Formula Student events against other university’s teams.

You can read more about Formula Student here and more about us here

Aisler has been our main PCB supplier since 2021. Their excellent online Gerber viewer and support for KiCAD board files make ordering our PCBs quick and effortless. The high quality of the PCBs, along with fast manufacturing and short delivery times, streamlines our process of developing, testing, and iterating. If mistakes are made—and we definitely do make them—Aisler’s revisioning tool is an invaluable resource. It allows us to easily order updated versions of our PCBs, helping us continue the car-building process without delay.

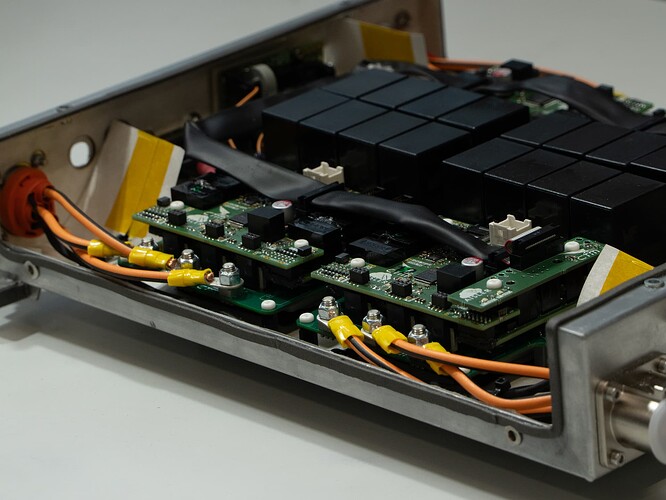

This year we decided to develop our own motor controllers. Self developed motor controllers can provide significant improvements in terms of efficiency, packaging and control. We opted for a modular three PCB assembly for easier servicing and faster development. On the base of the stack is a power PCB with the DC link and power stage. The top PCB is our control board. Sandwiched in between is the gate driver board.

The motor controller is designed to work on a 430-600V battery, driving a IPM wheel hub motor each, with a peak power of 35kW per motor. So, for an all wheel drive Formula Student race car four inverters are used. The motor controllers receive the desired operation mode and the control setpoints via CAN FD.

We opted to go for a silicon carbide (SiC) mosfet module due to their superior switching performance and higher partial load efficiency compared to IGBTs. Due to the high dV/dt from SiC mosfets, the DC bulk capacitors need to be as close as possible to the power stage.

The gate driver board, as the name suggests, holds the gate drive circuits. It also has the main isolation barrier between the low voltage system (LVS) and the 600V tractive system (TS). The used gate drivers are Infineon 1ED3321, chosen for their advanced features like desaturation protection and active miller clamp.

The main microcontroller running the FOC algorithm is a STM32G474. A microSD card is used for logging. We also have a tiny companion FPGA for communication with Heidenhain encoders.

We are glad to have Aisler as a long-term sponsor and we want to thank the whole Aisler Team for their support over the past few years. Together, we’ve achieved our first podium results in international Formula Student competitions and hopefully many more will follow in the future.