Hello fellow makers,

We are Campus Tirol Motorsport, the Formula Student Team from Innsbruck. Each year, we design and build a brand-new electric race car to compete in international Formula Student competitions against teams from universities around the world.

You can read more about Formula Student here and more about us here

Aisler has been our primary PCB supplier since 2021. Their excellent online Gerber viewer and support for KiCad board files make ordering PCBs quick and effortless. The high quality of the boards, combined with fast manufacturing and short delivery times, significantly streamlines our development, testing, and iteration processes. When mistakes happen—and they definitely do—Aisler’s revisioning tool becomes an invaluable asset. It allows us to easily order updated versions of our PCBs, helping us to keep our car-building process on track without delays.

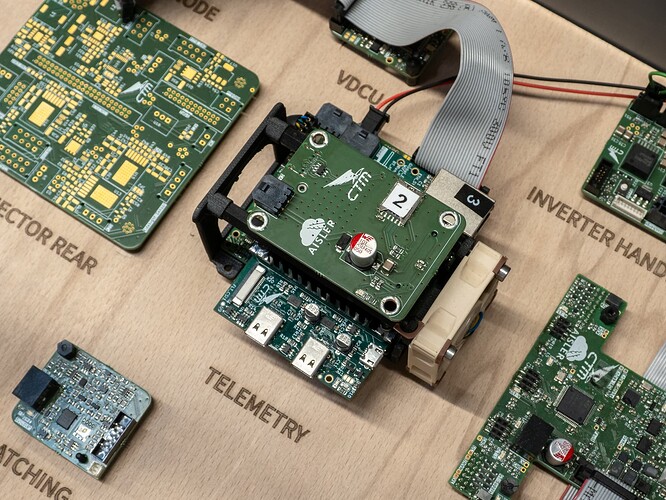

This year, we developed the third revision of our custom Telemetry System—the brain of our car. It logs all CAN bus data as well as the camera feed. The system is a stack of three PCBs:

- Main Board – supplies various required voltages and includes four CAN FD transceivers

- Module Carrier – mounts the Raspberry Pi Compute Module 5 (CM5) and handles all high-speed data connections

- LTE Module – provides wireless connectivity for remote data access and updates

At the core of the system is the CM5, mounted directly on the carrier PCB. This board manages all high-speed signals, including two USB-C ports supporting USB 3.1, a high-speed M.2 SSD for data logging, and two CSI interfaces for in-car cameras. The LTE module, connected via USB-C, enables a direct wireless link to the car. Through this connection, we can adjust parameters and view real-time data, allowing us to optimize test sessions and rapidly adapt key settings.

All our STM32 microcontrollers run a custom CAN bootloader, enabling over-the-air (OTA) software updates via the Telemetry System. On boot-up, the system checks each microcontroller’s software version against the current version stored on GitLab. If any mismatch is found, the car automatically updates itself with the latest firmware. Additionally, all set parameters are sent to a dedicated logging channel on our Team’s communication platform to better track and document the car’s configuration.

For enhanced live data visualization, we developed our own Live Telemetry Viewer, accessible via a web interface. This allows every team member to easily monitor metrics such as motor temperature, suspension travel, cell voltages, and CAN messages in real-time.

We are proud to have Aisler as a long-term sponsor and sincerely thank the entire Aisler team for their continued support over the past few years. Together, we’ve celebrated our first podium finishes in international Formula Student competitions—and we’re aiming for many more in the future.