PCB Development for our locomotive, ADLER 2

Hi, we are Team EAGLE from the Institute of Technology in Nuremberg, Germany.

We are a group of 10 full-time student from different technical backgrounds and participate in the Railway Challenge, which is similar to Formula Student but for trains with a gauge width of 10 1/4 inches (26 cm for us Europeans). There are many disciplines we participate in, e.g. traction, auto-stop, location announcement, energy recovery, business case. A competition for everyone. This year, we set out to develop a completely new locomotive as our old one suffered from reliability and therefore performance issues.

We decided to pivot to our own PCB development for some functions to control more parts of the locomotive while using proven, off-the-shelf electronics for common tasks on a locomotive like motor control or battery monitoring.

For the manufacturing of our PCBs we turned to Aisler, as some team members have used their service professionally and for their studies in the past and were happy with the turn-around time, quality and service.

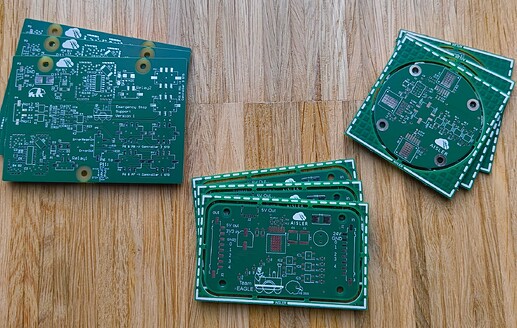

The PCBs

For the locomotive, we designed 3 different PCBs. Each was originally designed by a different engineer. We used varying software to design the PCBs. Nonetheless, it was easy in all cases to upload the necessary files to Aisler and get them manufactured correctly.

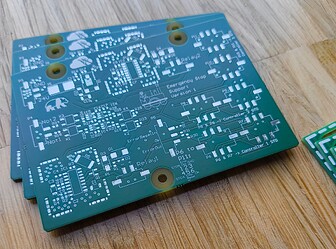

Emergency Stop Support

To facilitate the braking and safe operation of the locomotive, the emergency stop support PCB was introduced. The rules of the competition demand that the emergency stop function shall not rely on software, shall be directly electrically or mechanically actuated and that a failure of a component should not reduce the available brake effort by more than 50%. Therefore, the PCB incorporates two redundant emergency stop circuits that drive one relay in the supply of the motor controllers each. Additionally, the Safe Torque Off (STO) function of the controllers is used to ensure that no tractive effort can be applied in the case of an emergency. Also, the pneumatic brake calipers are actuated by this PCB. The PCB is crucial for the safety of the locomotive and allows easy compliance with the rules.

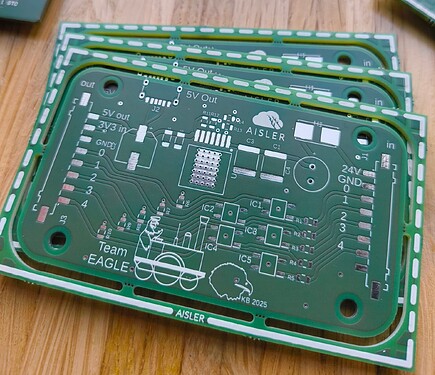

Location Announcement Utility

Our team set out to participate in the optional location announcement challenge. While passing specific landmarks or attending/finishing challenges, a visual and acoustic announcement must be done. To implement this function, we initially found a company that not exclusively designs acoustic sound systems for elevators. One product was particularly well suited for our application and featured the selection of the correct announcement by a binary address. For the visual announcement, we opted for a customised LED matrix. To allow the simultaneous control of both systems with the same signal, we designed the location announcement utility PCB. This PCB supplies all relevant subsystem with power and shifts the control voltage of 24V to 5V where necessary.

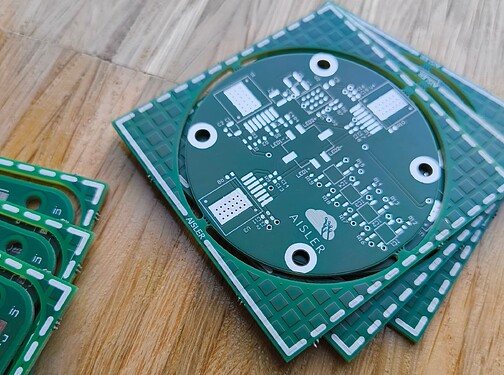

Driving Light

Our locomotive is equipped with several driving lights. As an innovation, we introduced a high beam for dark and long corridors you might encounter underground or night rides. The lights use LED drivers for 2 different LED channels, either 2 white LED channels for the high beam or 1 red and 1 white LED channel for the regular driving indication. For heat transfer purposes, the LEDs are placed on a separate PCB and fitted with a heatsink. The whole assembly is put into a 3D-printed casing with a glass fresnel lens from another sponsor.

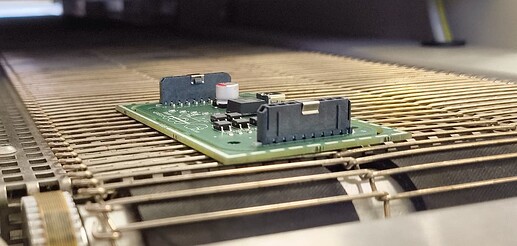

Circuit Board Assembly

Our university got a pneumatic, manual assembly station. With the provided stencils, we applied the soldering paste ourselves and populated the boards. After spending some time in the reflow oven, the PCBs tumbled out of it ready for use.

Summary

With the implementation of our own PCBs we were able to achieve 1st place at the competition in Germany as well as 2nd place at the competition in England. It was our first participation in England and our first win in Germany. Considering our relatively short team history, we are very proud of this years results.

We thank Aisler for their generous support enabling our success. They allowed us to customise our locomotive at the right systems and offered us the flexibility to balance cost, functionality and reliability.

If you would like to get to know more about our project, follow us on LinkedIn or Instagram.