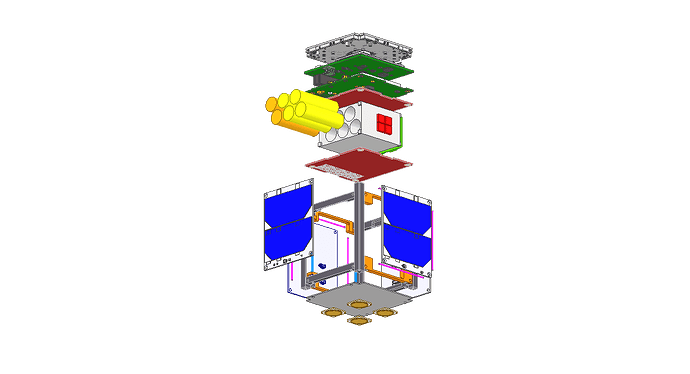

TeideSat is a team of students and ex-students from Canary Islands universities. Our goal is to design, assemble and launch a nanosatellite following the cubesat standard. It’s based on a cube about 10x10x10cm.

Once it’s placed in space, this cubesat will have two missions:

- The first and main one is to establish optical communication through high power LEDs. We would like to receive information from the cubesat, like its status, measurements and position in relation to the Earth. Thanks to this information, we are able to investigate how to mitigate satellite light contamination due to their reflections and thus, learn how astronomic pictures could be taken with less interference.

- The second one is to analyze how different memory units work in space without any protection. We will place different memories (NOR, NAND, EEPROM, etc) and store specific information to see how cosmic radiation affects them.

Our nanosatellite is divided in different subsystems:

-

Battery Management Subsystem (BMS): it manages the batteries protection circuits and outputs a clean power channel to use with the EPS.

-

Electrical Power Subsystem (EPS): the EPS is splitted into two categories: high and low power. High power one is dedicated to supply the four LEDs to provide enough energy since it has a really high consumption compared to the rest of the satellite.

-

Attitude and Determination Control Subsystem (ADCS): This subsystem uses a GPS and an IMU to determine the location of the cubesat in space. This way, we are able to focus the LEDs face to the Earth.

-

On-Board Computer: Our main control device to manage all the internal tasks and also the responsible of act depending on the situation (shadow zone, low battery, emergency cases, etc)

We also have a department dedicated to the structure of the cubesat, its thermal dissipation, etc.

Currently, we are nearly ending the first design phase of the subsystems. One of our plans is to design different boards with different ic’s for our EPS. We need to make some tests about which converter is the most efficient for our case, their limitations and other tests like thermal dissipation and stress testing to simulate the space environment.

Thanks to Aisler, we are able to design and test almost inmediatly! The test process is one of the longest ones since we need to make sure each component is suitable for our space mission.

We expect to have a cool design season very soon!

Some AISLER boards for our optical experiments.