First, a look at the current situation

The AISLER’s Design Rule Rating of your PCB topic states that:

Soldermask openings should have the size of the underlying pad, as the openings are automatically enlarged by us.

Aisler’s custom KiCad design rules forbid soldermask margin override.

The Soldermask Opening Adjustment topic states that:

Our System assumes that optimized soldermask openings are larger than the copper pad. Square, Rectangular and Round openings can be optimized, irregular shapes will be left as is.

A potential problem

If I understand it correctly, polygons on the copper layers will not have the soldermask automatically moved back. This could results in issues, could it not? As stated in Soldermask Opening Adjustment:

A misalignment of the soldermask might cover up parts of a pad, , resulting in less space to mount a component.

Should it be concluded that in general, a custom soldermask margin is discouraged but, in some cases, it is required?

If this is the case, perhaps the custom design rule should result in a warning?

The consequences of a custom soldermask margin

What happens when the design rule is ignored and a custom soldermask margin is requested/ordered? Are there any disadvantages or potential problems related to this given that the custom margin is large enough, e.g. >20µm?

Following these questions, why is the custom soldermask margin forbidden in the first place? Is it to simplify PCB design as the designer does not have to keep the soldermask margin in mind or prevent too small margins?

Use case

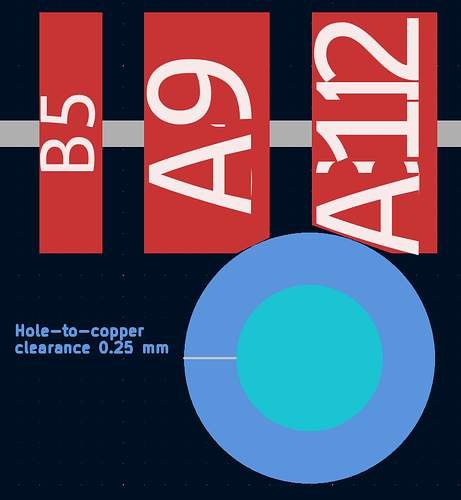

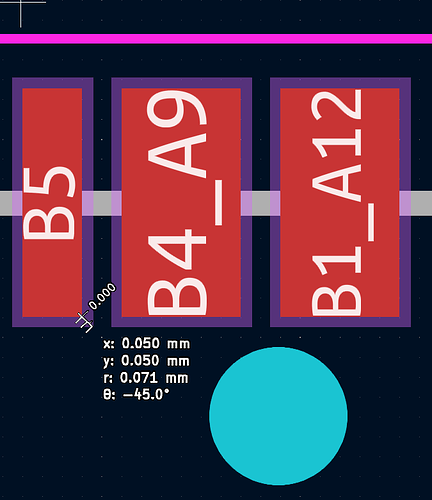

In a project, I have a NPTH that is very close to some pads (185 µm). In order to comply with Aisler’s 250 µm constraint, I cut parts of the pads’ corners.

Now I’m wondering if I need to apply a custom soldermask margin despite the design rule.

The manufacturer of the component has the following custom soldermask margin.

Looking forward to your insight,

Matthias