Overview

The aperture (opening) of a stencil needs to be adjusted based on the stencil and footprint for optimal printing results. We use an automated system to detect whether a pad in the paste layer has already been adjusted or not.

Why is it required to adjust the Aperture?

Adjustments in the aperture improve the printing and reflow process. The paste aperture is typically made smaller than the copper pad to account for stencil misalignment and to control the volume of solderpaste that gets applied, too little and no solid connection is made, too much and shorts can form. Reputable component manufacturers will often provide an example landpattern together with a recommended stencil thickness.

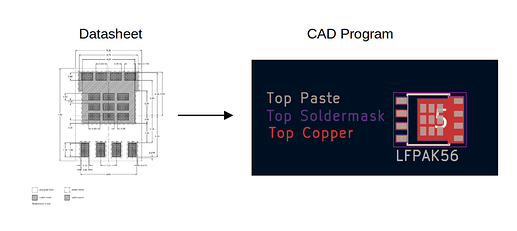

Aperture Design in CAD

When drawing a custom aperture, use the recommendations in the datasheet. Make sure to disable the automatic paste layer for the pad, you can now draw the desired aperture on the corresponding layer.

| CAD Program | Paste Layer |

|---|---|

| KiCad | F.Paste |

| EAGLE | tCream |

| Altium | Top Paste |

| DipTrace | Top Paste |

Automated Aperture Adjustment

Some designs may not have adjusted stencil apertures, to provide an optimal stencil we use an automated system to adjust the aperture. In this paragraph, we explain how the system works and what its capabilities are.

Our System assumes that optimized stencil apertures are smaller than the underlying copper pad. Square, Rectangular and Round apertures with sides larger than 250 µm can be optimized, irregular shapes will be left as is.

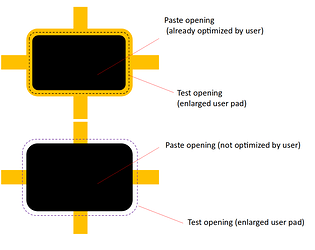

When a design is uploaded, our system will create a test opening/area which is 10 µm larger than the stencil aperture in the design. The system will now create test points along the outline of the test opening/area and probe if the test shape touches copper. If all test points touch copper, we assume the aperture was already optimized.

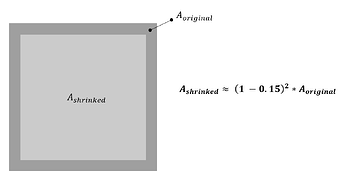

If some points do not touch copper, we assume the stencil aperture was not adjusted, we will apply our adjustment then, the opening will be shrunk by (1-0.13)² * A-original. Small openings where one or more sides are smaller than 250 µm will not be shrunk as to not impact the printing process.

Limitations

Gerber files do not contain any information about pads, so we can only detect whether copper is present or not. This means that the automatic system cannot correctly detect Pads placed in copper fills, as a result, they will not be adjusted. We do not categorize this as problematic as most issues during paste printing stem from smaller pads which typically are not connected to a ground plane.