Who is this guide for?

This guide is for beginners, and will cover the trace width selection for power traces, signal traces and manufacturing limits, more advanced topics like impedance, skin effect and others will be covered in other guides.

Introduction

When starting out with PCB design, you might ask yourself how to select the right trace width. No worries for simpler designs it’s not difficult.

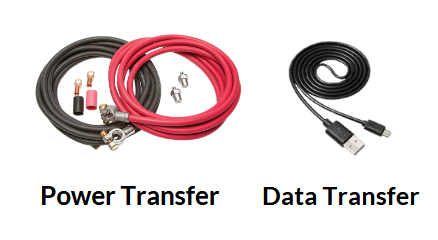

Let’s start with an analogy:

When selecting cables, you use Big/thick cables for power transfers and smaller/thinner cables for communication. While one could use thicker cables for data transfer too, they would cost more than needed. When designing, you should always aim for a solution that does the job well at a reasonable price. It’s the same for traces on a PCB.

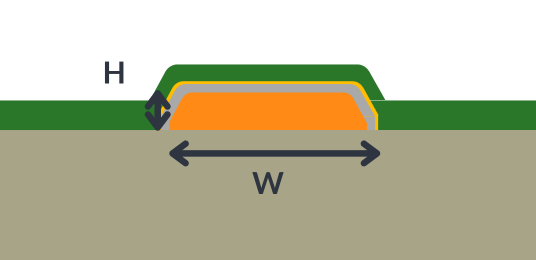

You can think of a trace like a very thin rectangular-ish cable made of copper. H notes the thickness of the copper and W the width.

Unlike cables, the copper thickness cannot be changed for individual traces only the whole PCB, so we can only change the width of the trace. 35 µm is the standard copper thickness for PCBs offered by us, so that’s what we’ll use for our trace width selection later.

Manufacturability

The smallest trace width that we can manufacture is noted in our design rules. For simpler low-cost designs, the smallest width is 200 µm, for more complex boards 125 µm. If the smallest trace width is not needed for your design, it is always a good idea to choose a larger width to make the manufacturing easier.

Signal traces

Signals typically only carry small amounts of currents, in the low mA or even µA range. A 125 µm thick trace can carry around 500mA! As you can see, it is the manufacturability that limits the trace width for signals. Pick a trace width of 200 µm, 250 µm, or 125 µm if you really need to squeeze in many traces in a small space.

Power traces

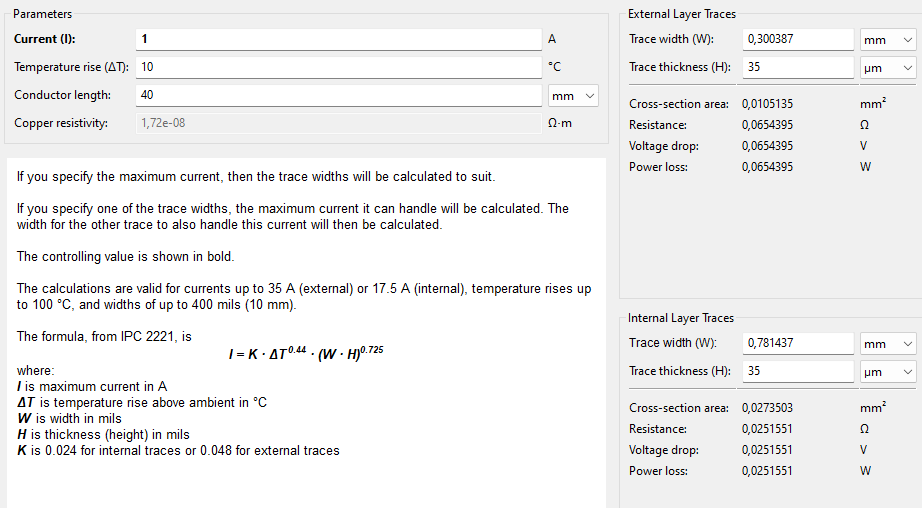

For power traces, we can use a trace width calculator based on a formula from the IPC2221 standard. Many PCB design tools like KiCad have them integrated.

Simply enter the current that your trace needs to carry, the length of the trace and the permitted temperature rise. Please note that the temperature rise is relative to the ambient temperature. If your device operates under room temperature, you can set the temperature rise higher for lower trace width. But if your project has to operate under high temperatures, you have to keep the temperature rise lower and thus must choose a wider trace.