We support Altium Circuit Studio ODB++ files, and prepare your design files for manufacturing using our automated software pipeline. If you have any questions or want to make remarks, please contact our support before ordering, as we do not read notes included in your project files.

How to prepare Circuit Studio ODB++ Export

Open up your PCB file and make sure all planes and polygons are updated, make sure to run the DRC to catch any errors, if there are any, please resolve them.

If that is done, navigate to Outputs -> Fabrication -> ODB++

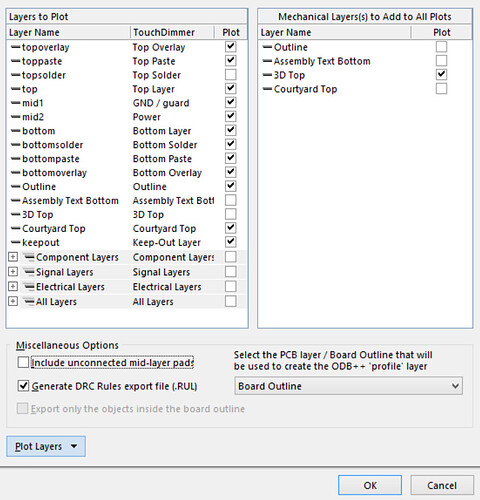

This will open a window with a few options. You can set which layers to include in the ODB++ file export and which layer will be set as ODB++ profile layer.

Make sure to include all the relevant copper, soldermask, paste and silkscreen and component layers. Set the layer you used for the outline to be included in the ODB++ profile layer.

When everything is set up, press OK and save the archive file. Now upload the file to our website, we will automatically generate the production data from it.

After we processed the ODB++ file you can inspect the boards using our board viewer.

We give a rendering guarantee that the boards are manufactured as displayed in our viewer. You can read this article if you are unsure how to use our board viewer or if you want to know how the rendering guarantee works.

Known PCB Design Tool issues

Issue: Component Part Numbers are not included in the ODB++ export.

-

Circuit Studio version: All

-

Description: The Component Part Numbers are not included in the ODB++ Output, and thus they need to manually entered in our BOM tool when an assembly is desired.

-

Workaround/Fix: None, the MPNs need to be manually entered. Circuit Studio was last updated 5 years ago, and unlikely to ever receive bug fixes. We recommend Altium or KiCad as alternative E-CAD programs.