2 Layer 1.6mm HASL

Last Updated: 07/07/2025

Imperial measures are rounded from metric measurements.

Design Rule Files

Do you want to start right away? We provide design rule files for Eagle, KiCad and DipTrace on Github .

The rules listed here shall always be used as reference.

PCB Dimension

We accept PCBs within these dimensions for our prototype service, contact our support if your design does not meet these criteria.

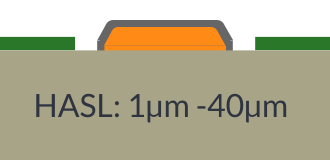

Surface Finish

We use lead-free Hot Air Surface Leveling (HASL) for this product portfolio, this surface finish is low cost and suitable for many applications.

.

Minimum Copper Features

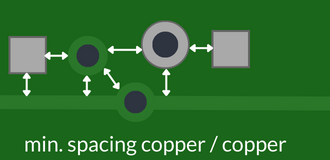

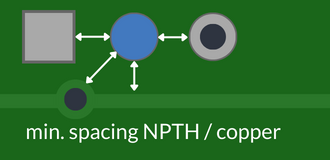

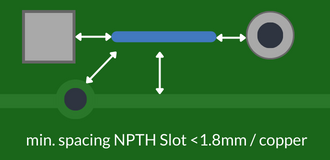

Minimum Copper Spacing / Clearance

| min. spacing copper / copper | 150 µm / 6 mil | |||

| min. spacing NPTH / copper | 250 μm / 10 mil | |||

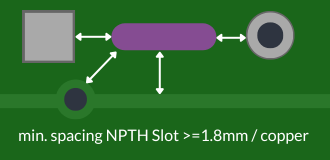

| min. spacing NPTH slot <1.8 mm / copper | 300 μm / 12 mil | |||

| min. spacing NPTH slot >= 1.8 mm / copper | 300 μm / 12 mil | |||

| min. copper to edge clearance | 300 μm / 12 mil |

Plated Through Hole (PTH)

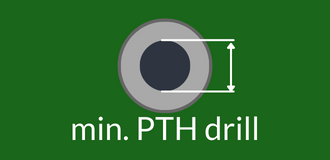

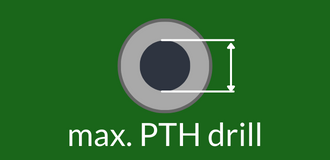

All drills with a diameter larger than 0.45 mm are categorized as plated through hole for component mounting, we will enlarge the drill diameter to compensate for the copper plating thickness to ensure that components can be mounted more easily.

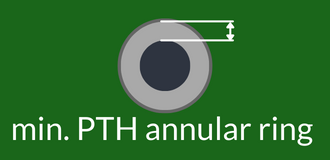

Vias

For economic manufacturing of simpler boards, we may increase the drill size up to a diameter of 0.45 mm. An annular ring of 175 µm is required, and the absolute minimum to compensate for the larger drill. Wherever possible, a minimal annular ring of 200 µm must be used.

Non Plated Through Hole (NPTH)

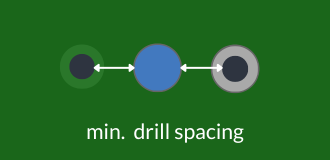

Minimum Drill Spacing

NPTH Slots

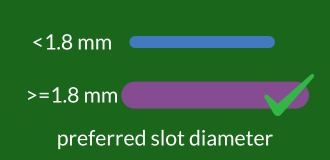

NPTHs Slots that are smaller than 1.8 mm are nibbled. This is a time-intensive process, so we reserve the right to limit the use of nibble slots in a design. Diameters above 1.8 mm will be milled and are thus preferred.

| preferred NPTH slot diameter | >= 1.8 mm / 0.07 in | |||

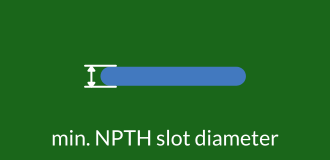

| min. NPTH slot diameter | 0.8 mm / 0.032 in | |||

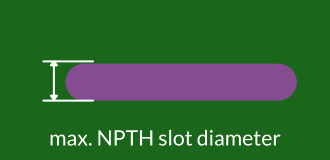

| max. NPTH slot diameter |

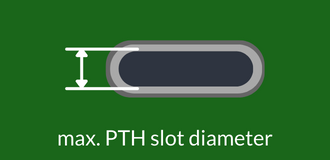

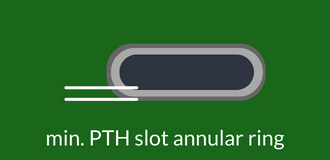

PTH Slots

| min. PTH slot diameter | 0.7 mm / 0.028 in | |||

| max. PTH slot diameter | 2.6 mm / 0.11 in | |||

| min. PTH slot annular ring | 300 µm / 12 mil |

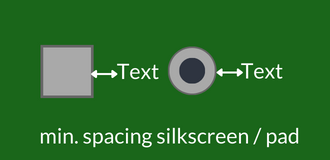

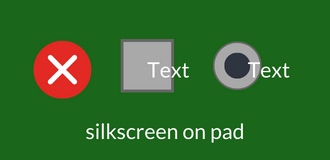

Silkscreen

We use Peters SD2692 ink for the silkscreen on our PCBs and apply it using the direct printing method. The smallest supported width is 150 µm / 6 mil, all silkscreen features with a width less of that will be adjusted. Silkscreen printed on pads is not supported, we use openings in the soldermask as reference to cut away / remove the silkscreen in the affected area. Do not use the silkscreen to produce large fillings, designs which cover more than 25% per PCB side will be rejected.

| min. silkscreen text height | 800µm / 32 mil | |||

| min. spacing silkscreen / pad | 125 µm / 5 mil | |||

| silkscreen on pad | not supported | |||

| max. Silkscreen | 25% of Board size |

Soldermask

We use high-quality Peters Elpemer AS 2467 SM-DG green soldermask which is well suited for the HASL finish. Please refer to our soldermask specification for the electrical properties of the soldermask.

| soldermask dam between pads | required for HASL | |||

| min. soldermask dam | 100µm / 4 mil | |||

| suggested soldermask expansion | 50 µm / 2 mil |

Castellated Edges

Castellated edges are not supported with HASL surface finish, please order your design as 2 Layer 1.6mm ENIG board if you use them.

Additional Notes

- Buried, blind, micro or tented vias are not supported

- User-defined subpanels are not allowed, see also here

- Pressfit components are currently not supported.

- Countersunk and counterbore are not supported.